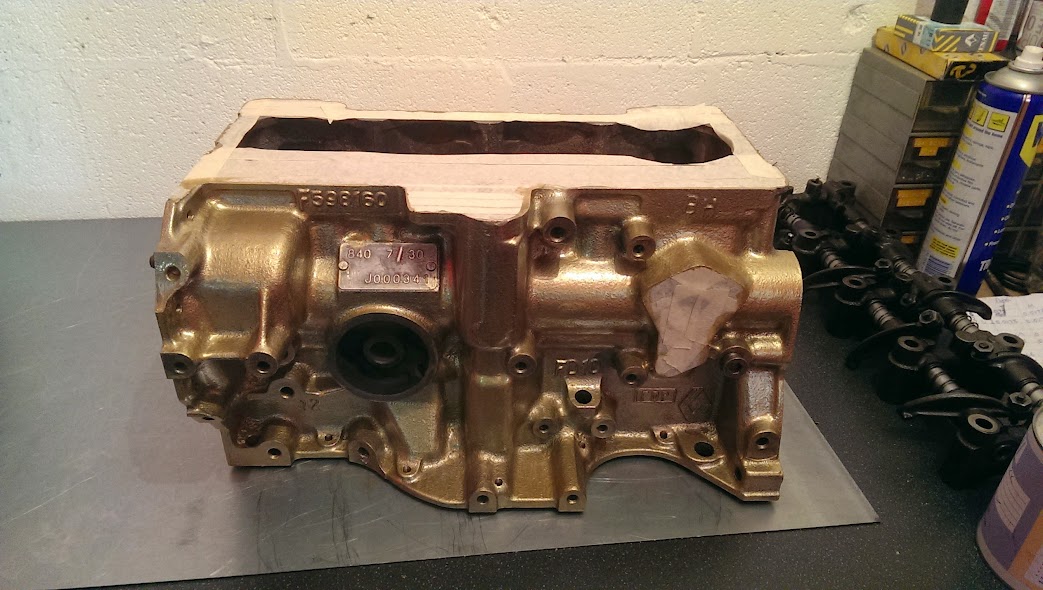

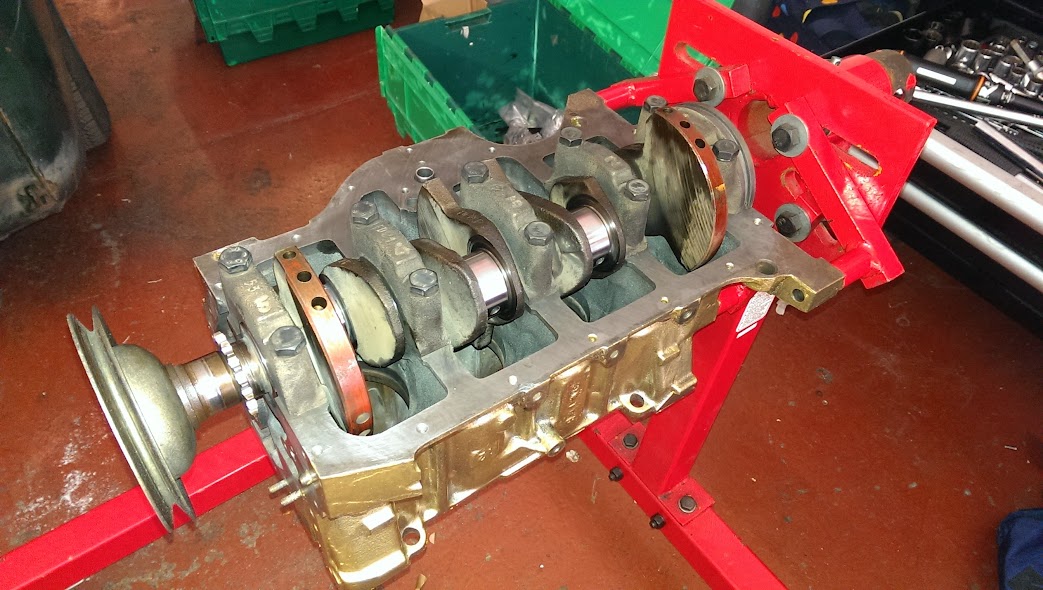

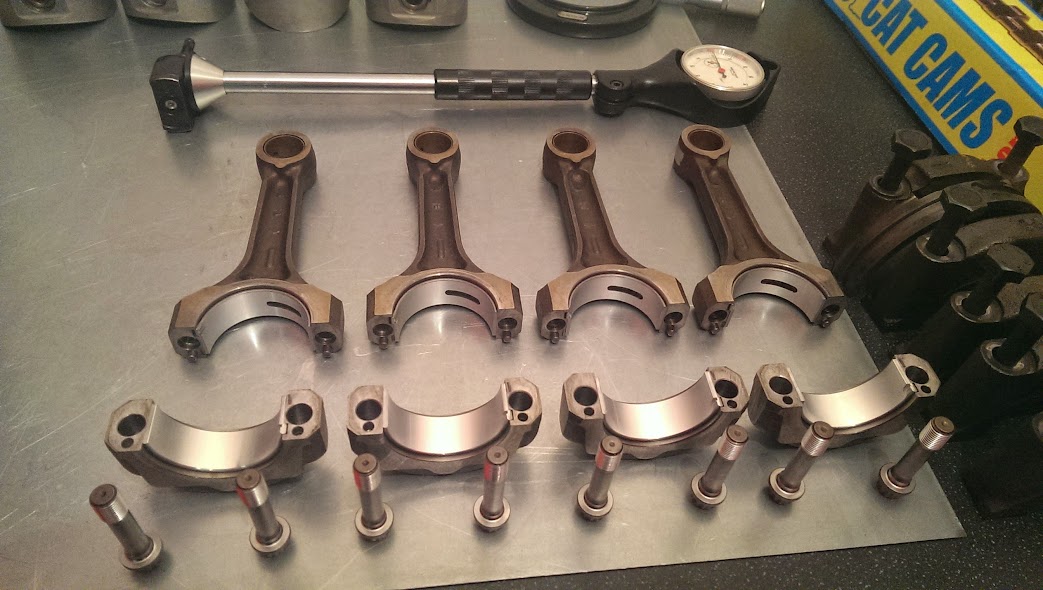

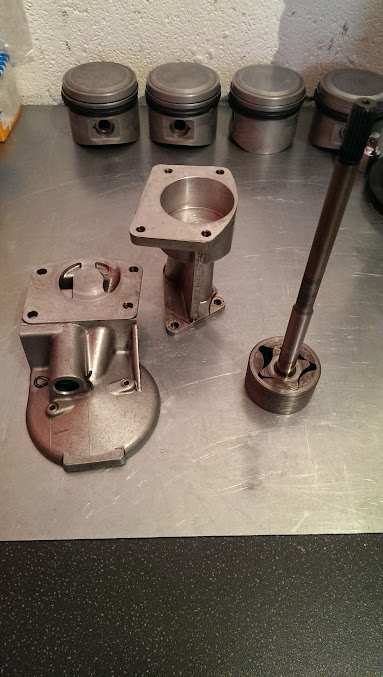

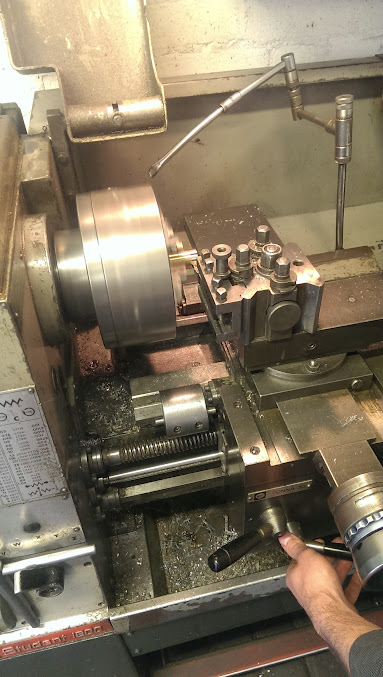

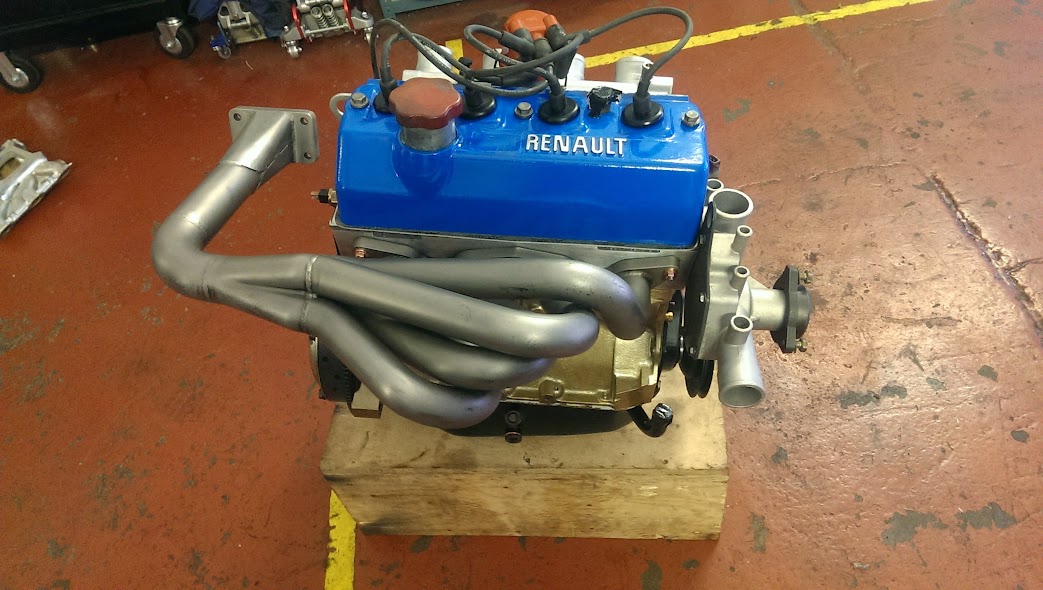

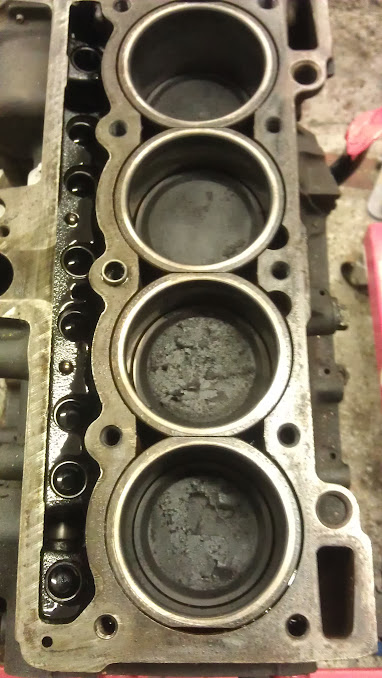

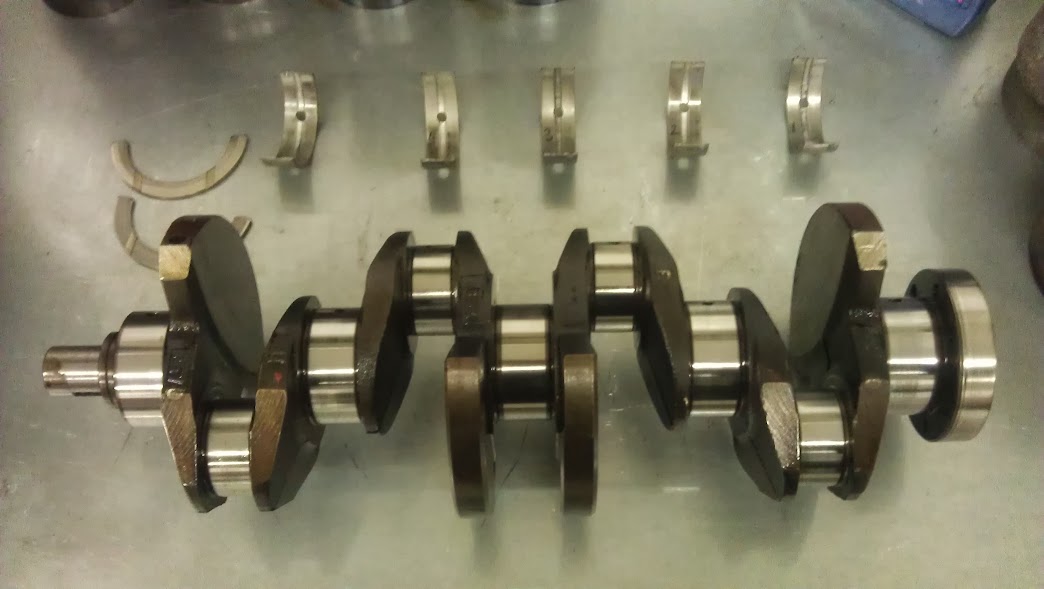

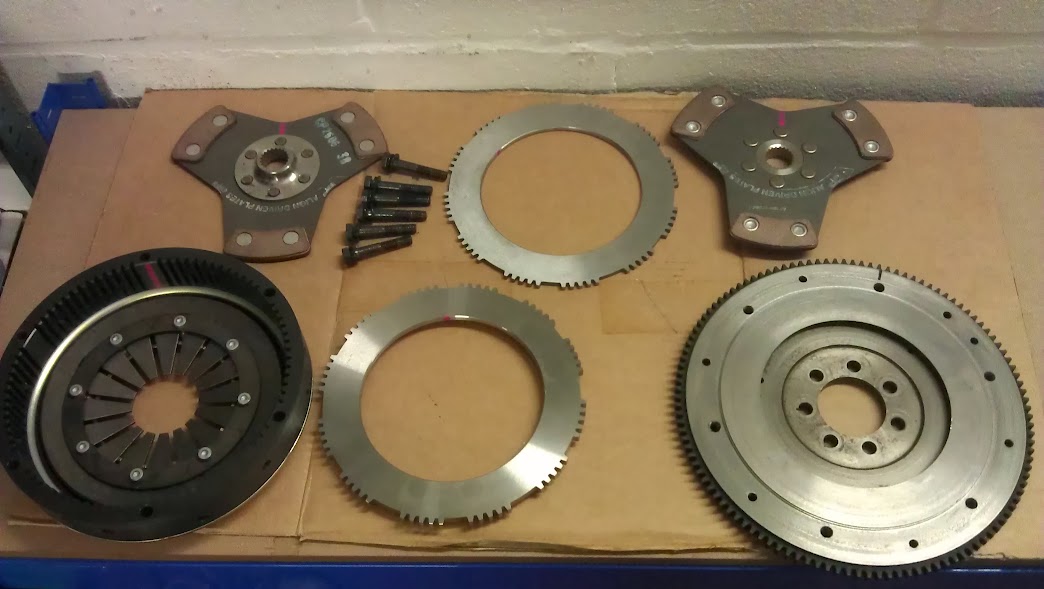

The low mileage engine was stripped and inspected. Apart from the obvious blow by, most likely caused from a life short journeys and limited use, the engine was in great condition. The block, crank, flywheel, pulley, rods and pistons were going to be reused so they were measured and then send off to the machineshop for any additional work and then lightened and balanced. Along with the rotating mass was a new AP twinplate clutch.

The T3 turbo required a rebuild so we decided to go for a larger billet compressor wheel, -34 actuator, 360 degree bearing new turbine and shaft and a larger .48 turbine housing which was flowed and polished.

Before

After

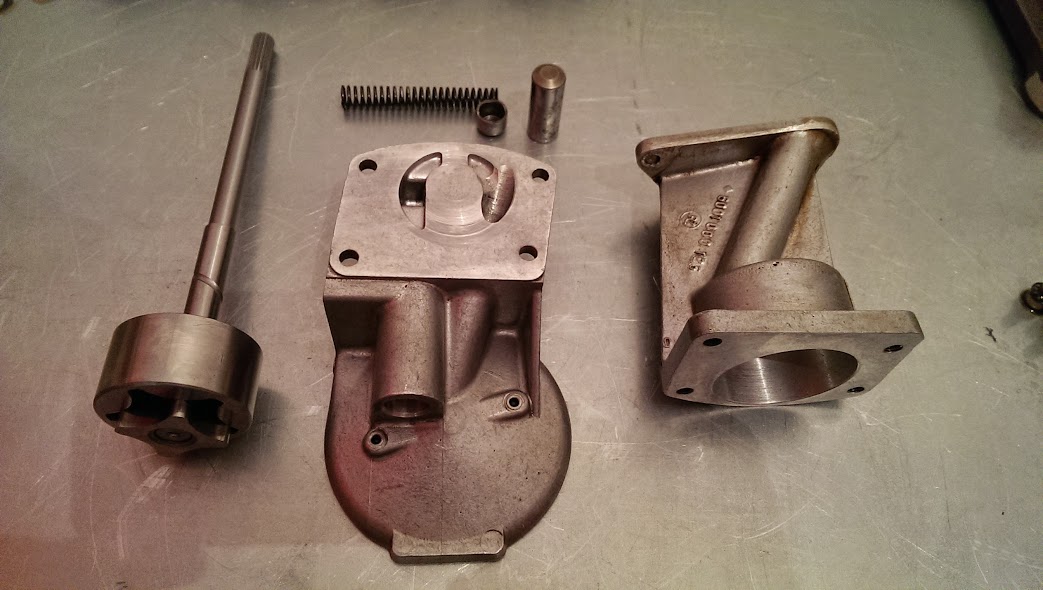

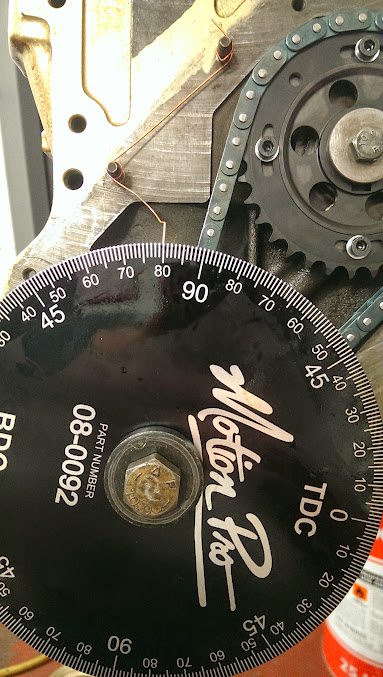

Some of the parts started turning up for the build. I used custom ductile steel liners from westwood, hybrid camshaft from Catcams, the followers were reground at newman cams, a vernier pulley from Catcams, new oil pump, sprocket and tensioner from 3S Developpments, all gaskets were OE Renault, Con rod bolts were replaced with ARP fasteners.