darrenbiggs wrote:Ok, so following on from Sunday's chat outside the RatCave Martin.....

How many correction factors are there in the normal GTA ECU setup? I'm just curious. Obviously it adds a whole extra dimension in what you've now discovered the ECU will adjust and compensate for (still staggering that it can do so much utilising such little memory) but likewise where does that fit in alongside the likes of Emerald, Adaptronic etc? Do they perform any basic corrections eg for voltage - you mentioned it had a direct impact on injector duration so is there similar in the 3rd party standalone ECUs?

Darren,

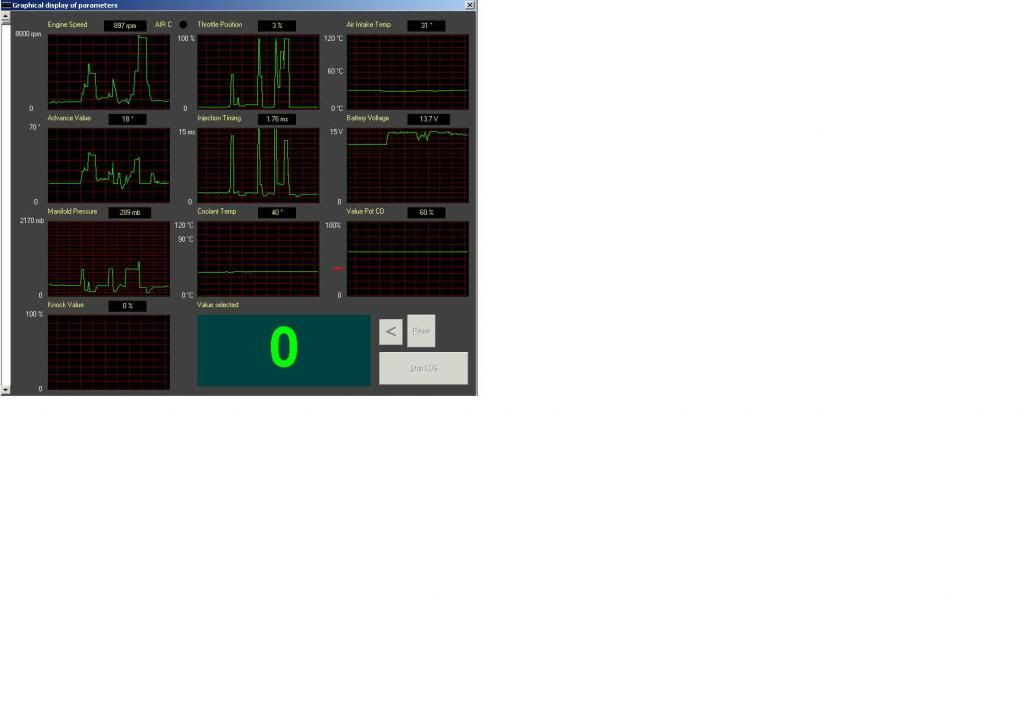

Besides the main Ignition (CARTA) and Fuel tables (CARTI) detailed above there are 12 other trim tables that I'm now working with in 255 byte paged address space occupied by the PROM address - $100h to $1FFh. The actual firmware was written directly in assembler to keep the code very compact and as fast execution as possible is very neat and compact and is stored in the MPU ROM address space $F000 to $FFFF ie. 4k bytes!! 4k bytes are running your car in a GTA turbo - I bet you can't even write your name in 4k in Word in MS. That's incredible when you think it has knock sensing, ignition roll back, idle speed regulation, and transient fuel enrichment to name a few. Yes it's real basic, but it gets the job done- modern fine electronic control, larger resolution maps, and serious quantities of code and processor speeds exceeding the 1MHz internal clock by over a factor of 20 at least for the boggo stuff still hasn't put the Renix 1 with appropriate mods to shame.

So the trims (put in the familiar terms for the later versions of the ecu):

TABS - rpm break points, not present in the Renix 1 ecu (or rather the PROM address range ie can be changed), and believe they are fixed in the firmware, I gave the values previously. This may be considered an issue in that you can't "re-bunch" the available load lines to suit the new engine characteristic i.e. put the smaller rpm step points around your critical engine characteristic transition points e.g. induction tuning, cam performance characteristics, turbo spool etc; but as it turns out this isn't a problem as DG noted, the turbo PRV engines all fall into a similar rpm range / transition characteristic, so not such a big issue - the turbo is an extremely effective lever in terms of the engine tuning being more about feeding heat and flow to the turbine than the engine parameters per se, with the compressor wrapping around the engine as a closed loop feedback system.

REGMAX - peak rpm cut, this is a brick wall with the Renix 1 at 6200 and is not adjustable. Working on an electronics solution to this...

REGREP - rpm point injection cuts back in after a REGMAX event, as above... adjustable in the later ecus ie LeMans, R21, R25ph2, R19, A610, BiSaf, etc...

TABZC - determination of the critical zone for knock, used with the level sensitivity table per rpm band - present in the Renix 1 and critical.

TBATA - ignition advance correction (trim table) with intake air temperature - present in the Renix 1 and critical for highly tuned engine.

TBATE- ignition advance correction (trim table) with water temperature - present in the Renix 1 and critical for highly tuned engine.

TBAVR - idle speed regulation through advance control correction with water temperature. If you disconnect the idle value, the engine idle speed is maintained at the desired set point by this trim table, and you will hear the engine speed hunting up and then back down as it resets. it's pretty basic, doesn't hold the engine speed like an ironing board that modern day standards expect, but it keeps it running close to where it needs to be and doesn't stall...

TRRDEM - effectively idle valve control with water temp.

TBDEM - starter injection / fuelling trim table - big injectors need to set this one or will have flooded starts.

TBBAT - injection duty cycle trim with battery voltage / condition - as you mentioned above Darren, change injector characteristics (type, impedance etc) then this will need to be modified or the fuelling could easily be a long way out and even prevent starts and re-starts both hot and cold engine.

TABA - correction of fuelling post warm-up - this is critical as I have found, along with the next one (trim table).

TABB - correction of ignition advance post warm-up.

TPPRS - acceleration enrichment, driven by the delta change of pressure at the MAP sensor and water temp.

TBISO - duty cycle correction of the idle speed - control loop period against water temp. Not changed it...

TRMIN - idle speed control valve minimum opening against water temp.

As to the aftermarket ecus, yes they do have these corrections, or equivalents that can be setup to perform the same functions or achieve the same results. Some are better than others, and comes down to what you want to achieve. I guess more of the issue is knowing what values to put in the various tables, than necessarily how many, how versatile, and the degree of resolution achieved. An engine can be pretty tolerant of mixture variations and make the same power putting emissions to one side, well certainly in turbo forced induction (well pump gas than methanol for example), less so on ignition timing however. Hence, you can tune and run an engine more than adequately with an ecu with somewhat less sophistication than modern technology, just understand the compromises. On example of this point, all the later OE ecus from the Fenix 3A (R25 atmo), LeMans, and R25 turbo ph2 ecu onwards all had the addition of closed loop lambda control for idle speed as an improvement towards fuel economy and more importantly emission regulation compliance.

IMO if you know how the basic engine responds, and have built up the necessary experience of it, then you should get a good result on almost any ecu, simply by the fact that if a bit of code 4k long on an 8 bit processor can crack it, then anything after that should do better!

Does that answer your question?

Cheers,

Martin