.

Andrea, was the below surface prep of the inside of the block your own, or something already there (green stuff)? If your own, what were you using please, looks good?

Brian, I take it you are likely looking to go 3ltr even-fire, when you are out searching, look for the head castings without the ugly smog port in the exhaust, as follows:

You don’t really want this one:

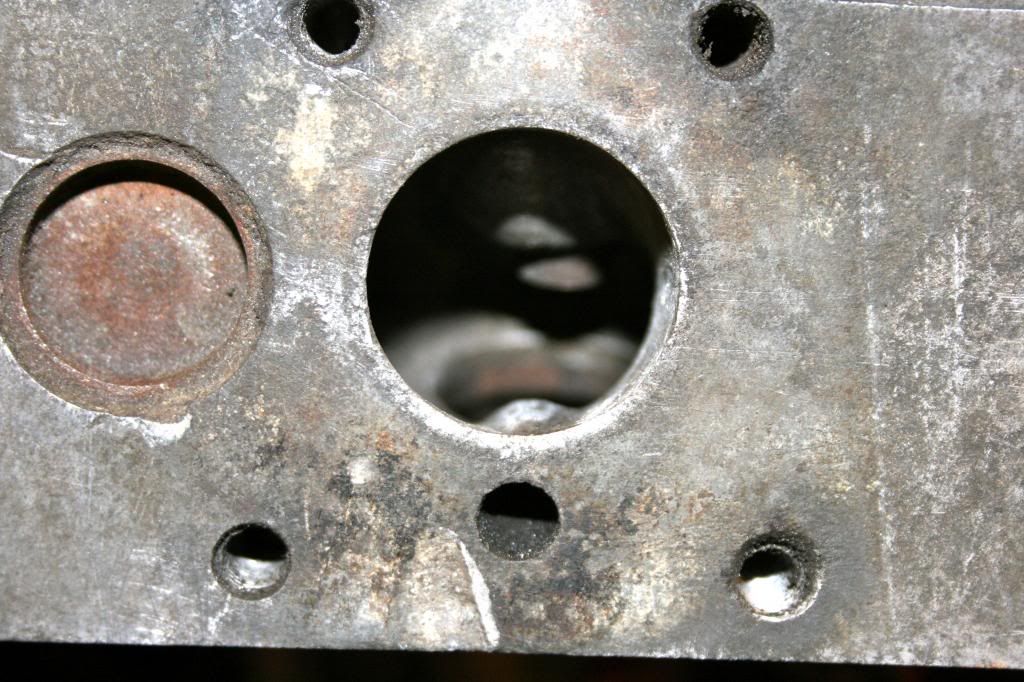

Brian, and Johnb, the below is the same head casting as yours (current R30, A310, GTA atmo, GTA turbo), and a quick 3 angle valve job to take the 3ltr even-fire n/a 46mm inlet (from 44mm on a 30 deg seat) on 30, 45, 70 seat cuts. The inlet throat was 40.8mm with a port volume of 89cc and exhaust taken up to a 38.5mm valve.

Started out as a bit of an ugly mess:

There are several engine rebuilds going on with various members, I though I would collect some thoughts, and a few things to look out for, and it would be good to share others experience, so join in, as we can all benefit.

As previously mentioned warped heads, also look for pickup on the cams and the cam bores in the heads, especially if they are tight or don’t want to be removed:

Definite witness on the back of the cam is either tight or closed up clearances (hammered or burnt seats), or potentially warped heads:

Look for distressed cam lobes, and valve to piston contact, although this shouldn’t happen as there is plenty of clearance valve-piston, even on the larger 46mm inlet there is over 250thou:

It is worth doing a vacuum check on your valve seats to ensure they are good (or have someone do it for you, don’t assume they are good, you will be surprised), especially with the 30 deg seat on the 44mm inlet, as it doesn’t self centre as well and has a lower contact face pressure for the same spring force as a 45 seat.

Then some other musings as I think back over stuff, and worth checking whilst doing your build or planning…

O-rings on the water divider to the block, make sure you have the right size, and fit without pinching, or they will leak:

Given the age of these engines and vibration, I think we are likely to see more fatigued items; this water pipe at the back of the heads with the turbo water return circuit is prone, and also very delicate when removing the union… so word to the wise when loosening and tightening up, don’t stress the brazed joint or you may be inflicting a latent defect to cause you problems later..

If the engine is coming put, then replace these fuel lines, just false economy not too, they are likely all hard now or even leaking, and too critical not to replace in my book…

There is also the water heater water pipes at the back of the engine in the same vicinity, and hence believe worth changing these whilst you have it all out, than experience a total water loss on the road or the circuit at a later date... a lot of this old stuff really doesn't like being disturbed, so worth considering...

Check your engine mounts, seems obvious

On a separate and positive note, the engine I have been putting together for my workshop friends at LTH Coachworks for their GTA is finally coming together (story in this thread

http://www.renaultalpineownersclub.com/ ... php?t=4899), and hopefully get put back in the car very soon. This a 2.5ltr with 3ltr even-fire n/a heads fairly substantially modified. Given the passage of time, flow testing and general playing about, and more specifically the flow development on the 2.5ltr heads and how to finesse them, then I wouldn't do it this way now... you live and learn...

It will be good to finally see this one back live and kicking, and allow me to tidy up and start the next couple of builds… may be my last too

Martin